PLA 3D Printing: Toxicity Control and Precautions

While PLA plastic itself is considered non-toxic, the high temperatures required for 3D printing can cause some potentially harmful fumes and particles to be released during the printing process. Read on to learn more about PLA’s toxicity and how to properly handle PLA 3D printing.

Factors influencing PLA’s Toxicity in 3D printing

When examining the toxicity of PLA for 3D printing, there are a few factors to consider. First, PLA itself as a material is generally considered non-toxic. It does not contain BPA or phthalates like some other plastics. PLA is approved for food contact and medical implants, showing that it does not leach harmful chemicals under normal conditions.

That said, the 3D printing process does introduce some risks of toxicity to be aware of. High temperatures are used to melt and extrude the PLA material layer by layer. At these temperatures, around 190°C to 220°C, PLA can start to decompose and off-gas potentially irritating or harmful fumes. Usually, PLA needs to reach over 230°C before significant decomposition occurs, but impurities in lower-grade PLA or small chamber sizes may increase risks.

These emitted fumes often have a sweet or noxious odor and may contain compounds like acids, aldehydes, ketones, terpenes, and volatile organic compounds (VOCs). Exposure can cause eye, nose, and throat irritation, headaches, dizziness, and nausea. Those with respiratory sensitivity may experience worse symptoms. Additionally, some ultrafine particles (UFPs) may be produced, which can accumulate in the lungs.

Minimize Exposure When 3D Printing With PLA

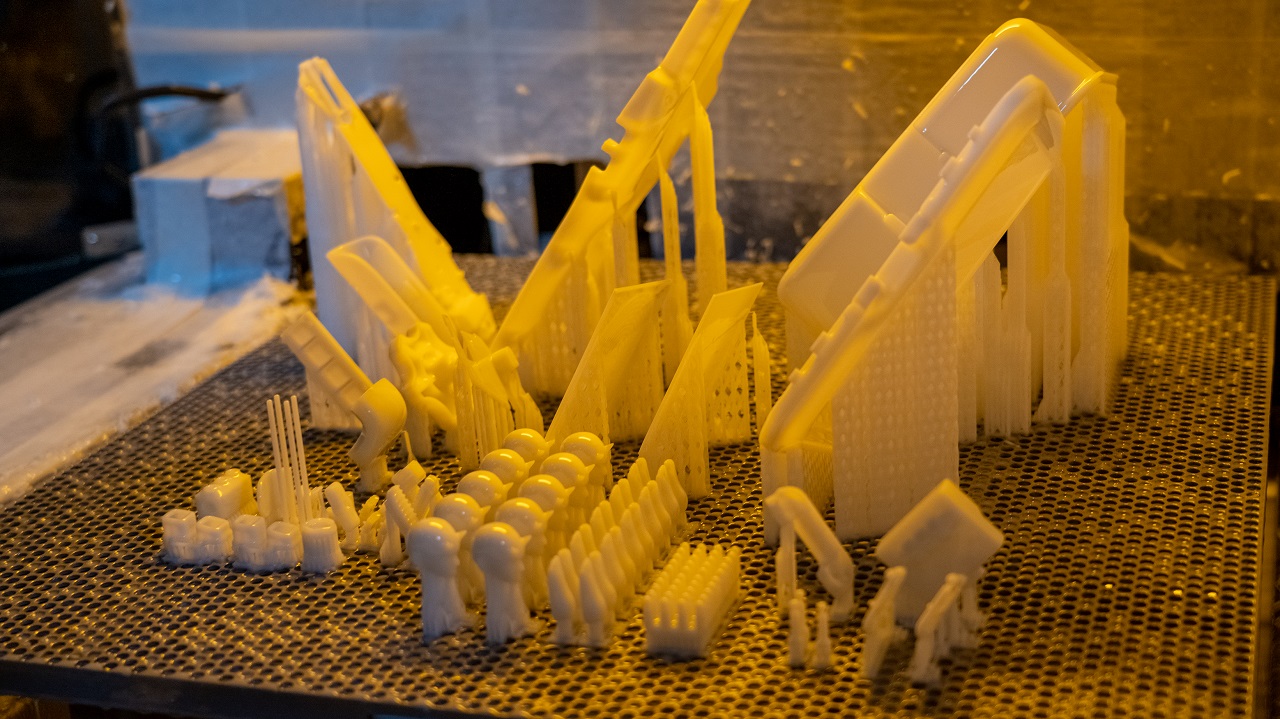

Fortunately, there are ways to minimize exposure when printing with PLA. Using higher quality, more pure PLA filament can reduce the risks. Open-framed printers or enclosures with fans and filters allow fumes to ventilate instead of accumulating around the printer. Place the 3D printer in a well-ventilated room rather than an enclosed space. Running the printer while no one is present or at night also limits direct exposure. Additionally, personal protective equipment like a respirator mask and gloves can provide protection. For those working with more toxic materials, such as resin, maintaining safety is even more crucial. Our comprehensive resin safety guide offers detailed instructions on managing harmful residues for a safer work environment.

In industrial settings, local exhaust ventilation systems are recommended to remove emissions right at the source. Fume hoods over printers, vents in windows, and exhaust fans preventing stagnant air will create airflow and dilution. Activated carbon filters adsorb gases, and high-efficiency particulate air (HEPA) filters capture fine particles. Regular maintenance helps prevent chemical build-up. Proper protective equipment for workers is also essential.

With the right precautions, PLA can be printed more safely. But it is still wise to be aware of the potential for some toxic emissions and particles during the printing process. Sensitive individuals, including children, pregnant women, the elderly, and those with respiratory issues should take extra care and minimize exposure. Try to avoid constant occupation directly in the same space as an active 3D printer.

Tips on Safe PLA 3D Printing

For most people doing occasional home printing, PLA is unlikely to cause major issues. However, take steps like keeping the printer in a garage or hobby room, wearing a mask when nearby, and allowing ventilation during and after printing. Avoid extensive use of lower-grade PLA filaments that may release more emissions.If you’re new to 3D printing and want to learn more about starting 3D printing safely and successfully, check out our 3D Printing Beginner’s Guide.

If you notice symptoms like headaches, eye irritation, nausea, or coughing when printing with PLA, stop your print and relocate the printer or improve air circulation. Long-term respiratory health is far more important than any 3D print. Be wise and minimize risks by using PLA safely.For an even safer and more convenient approach, consider utilizing professional 3D printing services.

Other bioplastic materials like PHA and PHB can reduce fumes, but less testing has been done on emissions from 3D printing them. PETG and ABS both require higher print temperatures that increase chances of release of UFPs, VOCs, and styrene compounds, making them less ideal.

In professional settings, employers should provide proper ventilation systems and protective equipment, monitor air quality, and implement exposure limits. More studies need to directly measure and characterize the emissions from 3D printing with various materials. This will allow definitive toxicity standards to be set.

The Bottom Line

Overall, PLA can be safely used for 3D printing by being aware of the risks and taking reasonable precautions. Use high-purity filament, allow ample ventilation, print when no one is present, and employ protective equipment as needed. Locate the printer away from heavy-use areas. By minimizing and controlling exposure, PLA’s advantages as a bioplastic can still be utilized without compromising health and safety. Just be cautious and informed when 3D printing with any material.