How Much Does a 3D Printer Cost?

Navigation

| Category | Price Range | Printer Type | Build Volume | Resolution | Material Compatibility | Notable Features |

|---|---|---|---|---|---|---|

| Entry-Level 3D Printer | Under $500 | Mostly FDM | Small (up to 6 inches) | 100-200 micrometers | PLA, ABS (basic materials) | Ideal for beginners and educational purposes |

| Mid-Range 3D Printer | $500 – $3,000 | FDM, SLA | Medium | As low as 50 micrometers | Plastics, some resins | Good for serious hobbyists, schools, small businesses |

| Professional 3D Printer | $3,000 – $10,000 | Varied | Large | Often below 50 micrometers | Flexible, composite materials | Suited for detailed prototyping, small-scale production |

| Industrial 3D Printer | Above $10,000 | Varied | Very Large | Down to 10 micrometers or less | Metals, ceramics, advanced polymers | High-volume manufacturing, professional engineering |

In manufacturing and design, 3D printing is a groundbreaking technology that allows for the creation of complex and custom objects directly from digital files,CNC machining represents a different approach to manufacturing. Comparing CNC vs. 3D printing is essential to appreciate their unique capabilities and differences. revolutionizing various industries. The initial cost of a 3D printer is just one aspect to consider; understanding how much it costs to actually 3D print things is crucial when budgeting for materials, maintenance, and operation.

Factors That Influence the Cost of a 3D Printer

Printing Technology

The type of technology a 3D printer utilizes is a pivotal determinant of its price. For instance, Fused Deposition Modeling (FDM) printers, which are among the most common and cater primarily to entry-level users, can range from as low as $200 for basic models to over $4,000 for advanced versions.Delving into what FDM 3D printing entails can help you understand the basics of this popular printing technology. In contrast, Stereolithography (SLA) printers start at around $2,500 due to their intricate laser-based process, soaring to $10,000 or more for industrial-grade models. Selective Laser Sintering (SLS) machines, known for their superior finish and material versatility, represent the upper echelon in pricing, often starting at $10,000 and extending well into the $50,000 range or beyond, reflecting their high precision and application in professional environments.

Build Volume and Print Quality

The cost of a 3D printer escalates with its build volume and resolution capabilities. Small to medium FDM printers with modest build volumes (ranging from 150mm x 150mm x 150mm to 250mm x 250mm x 250mm) are typically priced between $200 and $1,000. However, machines offering larger build volumes, essential for industrial applications, can cost upwards of $10,000. Resolution is another price influencer; higher resolution printers, capable of layer heights as fine as 20 micrometers, can double or triple the price compared to those with standard resolutions of 100 micrometers.

Material Compatibility

The variety of materials a printer can handle directly impacts its price tag. Basic FDM printers, which are compatible with standard materials like PLA or ABS, tend to be on the lower end of the price range. Conversely, printers designed to work with specialized materials – such as PEEK, ULTEM, or flexible thermoplastics – necessitate advanced thermal and mechanical properties, pushing their prices into the $5,000 to $20,000 range or even higher for those that can process metal or ceramic materials.

Brand and Support Services

The brand’s reputation and the extent of its customer service significantly influence the price. For instance, a 3D printer from a leading brand can cost 25% to 50% more than a comparable model from a less-known one. This premium ensures access to expert assistance, regular software updates, and warranty services, which can be crucial for operational reliability and longevity.

Additional Features

Features like heated beds, essential for printing with ABS or other high-temperature materials, can add $100 to $500 to the base price of a printer. Dual extruders, which allow for multi-material or multi-color printing, can increase the cost by $300 to $1,000. Advanced software features that enhance print quality and user experience can also add a significant premium to the overall cost.

3D Printer Price Categories

The 3D printing market caters to a broad range of users, from beginners to professional engineers and industrial manufacturers.

- Entry-Level (Under $500): Entry-level 3D printers are the most accessible, designed for individuals who are just stepping into the world of 3D printing. Priced under $500, these machines are predominantly Fused Deposition Modeling (FDM) types. They feature smaller build volumes, usually not exceeding 6 inches in any dimension, which suffices for crafting small objects or prototypes. The resolution in this category can vary but generally does not match the higher-end models, usually around 100 to 200 micrometers. Despite their limitations, entry-level printers have significantly improved over the years and can produce satisfactory results for casual users or educational scenarios.

- Mid-Range ($500 – $3,000): The mid-range segment is tailored for enthusiasts and professionals who seek a balance between cost and capability. These printers are counted as a step up in build volume, offering dimensions that can accommodate larger projects. Resolution also improves in this tier, with many models capable of achieving layer heights as low as 50 micrometers. This price range sees a mix of FDM and Stereolithography (SLA) printers, the latter beginning to appear more frequently as prices drop. Mid-range 3D printers are particularly appealing to serious hobbyists, educational institutions, and small businesses that require higher-quality prints and a more extensive selection of compatible materials, including various plastics and resins.

- Professional ($3,000 – $10,000): Professional-grade 3D printers are engineered for precision and versatility, catering to businesses and educational institutions with specific needs. These machines typically offer large build volumes, superior resolution (often below 50 micrometers), and the ability to print with a wide array of materials, including specialized filaments such as flexible or composite materials. Additionally, they may feature enhancements like heated print beds, dual extrusion, and advanced software controls. This category is ideal for detailed prototyping, small-scale production runs, and advanced educational purposes, providing the tools necessary for complex, high-quality projects.

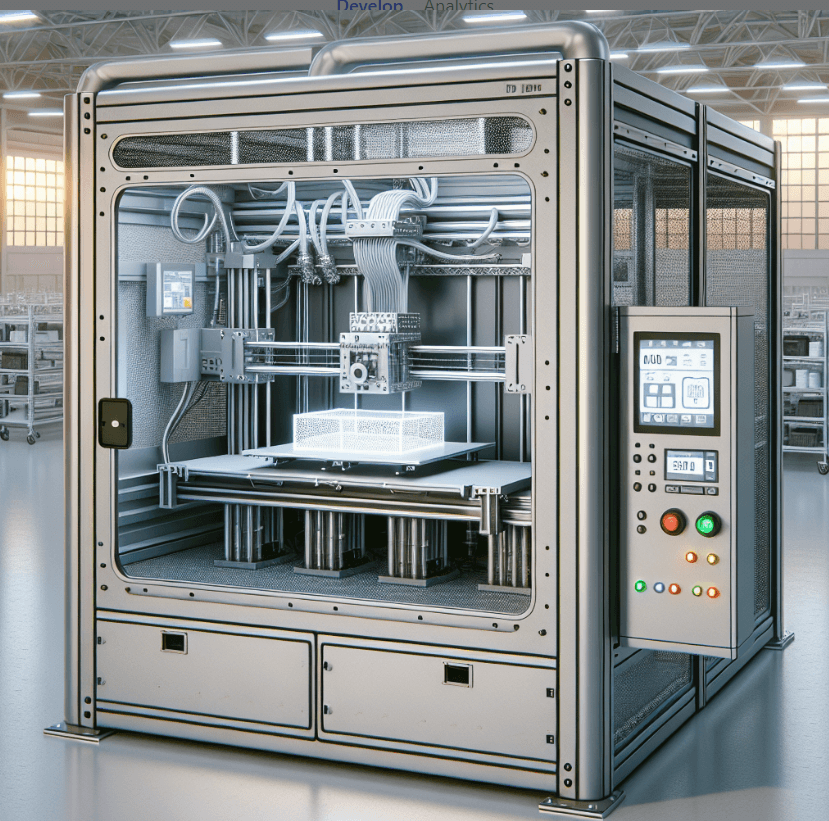

- Industrial (Above $10,000): At the pinnacle of 3D printing technology sit the industrial-grade machines. These printers are the workhorses of the manufacturing world, designed to meet the demands of high-volume, professional engineering, and production environments. Industrial 3D printers boast the largest build volumes, the highest resolution (down to 10 micrometers or less), and the ability to work with a vast range of materials, including metals, ceramics, and advanced polymers. They are equipped with state-of-the-art features such as continuous printing capabilities, automated calibration, and sophisticated monitoring systems. Industries such as aerospace, automotive, and healthcare rely on these high-performance machines to create parts that meet stringent quality and strength standards.

Final Words

The cost of a 3D printer varies significantly, hence the need to consider your specific needs, the type of objects you intend to print, and your budget before making any purchase.Naturally, when we talk about 3D printers and their capabilities, we should also consider the services that can assist us in utilizing these machines to their fullest potential. This is where QSYrapid 3D printing service aligns perfectly within this context.

With 30 years of experience in catering to all levels of 3D printing needs, QSYrapid embodies reliability and excellence. Whether you’re a beginner experimenting with your first entry-level 3D printer or an industry expert operating at the professional or industrial level, QSYrapid has the know-how to support you every step of the way.

Working with a wide array of printing technologies and materials, their services can vastly complement your 3D printing journey, regardless of the type of printer you use. From the simpler PLA and ABS used predominantly in FDM printers to specialized materials such as PEEK, ULTEM, or flexible thermoplastics compatible with high-end models, QSYrapid manifests versatility at its best.

So, if you’re looking for a partner to elevate your 3D printing endeavors or if you’re considering a more efficient alternative – remember, the complexity, volume, and precision required for your 3D printing projects can be expertly handled by QSYrapid, saving you valuable time and resources in the process.