3D Printing vs. Outsourcing: Which is Best for Your Business?

Navigation

- Low to Moderate Production Volumes

- Constrained Timelines to Meet

- Avoiding Significant Equipment Investments

- Lack of Specialized Skillsets

- Stringent Physical Property Needs

- Shielding Intellectual Property

- When to Transition In-House Eventually

- 3D Printing: Oursoucing vs. In-House

3D printing, also known as additive manufacturing, has disrupted product design and manufacturing across industries. While many companies have adopted in-house 3D prototyping, understanding when to outsource final production instead of attempting everything internally saves money. Weigh factors like production volumes, critical timelines, equipment investments, staffing experience, part physical properties, and intellectual property when deciding between outsourcing versus establishing complete in-house 3D printing capabilities.

Low to Moderate Production Volumes

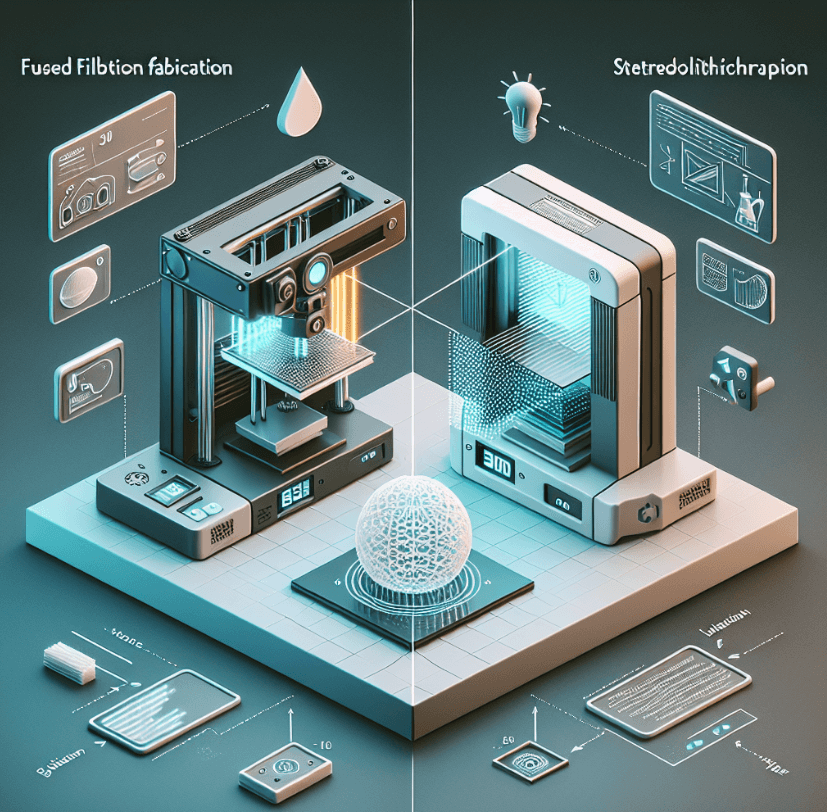

Additive printer output remains constrained versus high-volume injection molding or machining. Most common fused filament fabrication (FFF) or stereolithography (SLA) equipment struggle producing over 500 end-use parts annually requiring post-processing too like sanding and painting. Building business cases justifying printer investments, materials and full-time staffing proves difficult below these quantities. Opt for outsourcing production runs under 1000 units to experienced service bureaus efficiently leveraging extensive equipment.

Constrained Timelines to Meet

Designing components using 3D modeling software has become efficient enough for product development teams to iterate frequently when ideating new applications. However, the actual printing process occupying hours or days for single prints makes in-sourcing short-timeline production goals heavily dependent upon owning any printers. Outsourced bureaus with vast equipment parks deliver much faster turnarounds when market demands necessitate swift sales samples or crowdfunding demo unit prints.

Avoiding Significant Equipment Investments

Enterprise-grade production 3D printers easily cost $50,000 to millions leaving tiny startups and lean engineering departments hesitant purchasing outright initially before market validation. Sensor-rich systems also require extensive monitoring, scheduled maintenance, and parts replacement, minimizing uptime risks if handled internally by generalists and not dedicated technicians. Outsourcing sidesteps major capex commitments until higher production demands materialize over longer horizons, justifying ownership.

Lack of Specialized Skillsets

Mastering professional 3D printing fluently spans architecture styling for optimal printing results, materials sciences expertise around compositions and machining tolerances, post-processing, quality assurance, automation workflow integration, and application engineering connecting concepts to realities. Expecting engineers to become that broadly versed presents steep learning curves before truly stabilizing processes in-house. External experts fill any knowledge gaps instead.

Stringent Physical Property Needs

Additive construction poses unique challenges in getting uniform material microstructures to achieve specific strength, thermal, conductive, or cosmetic property targets. For applications like industrial tooling requiring resilience or medical implants needing biocompatibility, specialized equipment, and tightly controlled procedures become necessary. Have established service bureaus to ensure quality, guaranteeing parts meet specifications reliably until bringing production completely internally.

Shielding Intellectual Property

Cutting-edge products contain tightly guarded proprietary engineering and designs that are not shared openly. While today’s service bureaus implement confidentiality measures securing data transfers, some risk still exists externally. Evaluate trade secret sensitivity, competition levels and reverse engineering risks when weighing keeping all printing in-house or outsourcing production of patented products. However, once patents get filed, outside services provide healthy scaled output.QSY 3D Printing Services Company believes from the beginning to the end: Your intellectual property is the lifeblood of your business, ensuring its security is our mission, and we are happy to sign a confidentiality agreement.

When to Transition In-House Eventually

Organizations don’t usually outsource 3D printing forever. As technology matures, it’s crucial to regularly check how much you’re producing, the quality, the cost of testing, and whether your team has the skills. When your production exceeds 1,000 units, or your designs need frequent updates, consider moving 3D printing in-house to save money and improve margins.

However, for startups and small teams, outsourcing can help manage production without the heavy cost of equipment that might not be used all the time. But keep an eye on your sales and market trends. If your business grows and it makes financial sense, start doing your 3D printing in-house to cut costs as your products become more popular.

3D Printing: Oursoucing vs. In-House

| Aspects in Comparison | Outsource 3D Printing Production | In-House 3D Printing |

|---|---|---|

| Costs | Lower upfront costs as there’s no need to purchase equipment. Variable costs depending on volume and complexity. |

Higher initial costs due to purchasing and maintaining equipment. Fixed costs over time; more cost-effective at large volumes. |

| Expertise | Access to specialized expertise without in-house training. Less need for staff training and hiring. |

Requires training and development of staff expertise. Control over printing processes and quality. |

| Flexibility | High flexibility in scaling production up or down. | Fixed capacity; less flexible but can be optimized for specific needs. |

| Quality Control | Dependent on the service provider’s standards and consistency. | Direct control over quality standards and consistency. |

| Turnaround Time | Can be faster due to specialization of services. | Depends on in-house capacity and workload; can be slower or faster. |

| IP Security | Potential risk of intellectual property exposure. | Higher control over intellectual property and confidentiality. |

| Customization | Limited by the service provider’s capabilities. | Greater flexibility in customization and iteration. |

| Volume | More cost-effective for low to medium volumes. | Economies of scale kick in at higher volumes, making it more cost-effective. |

| Investment Risk | Lower risk as there’s no large capital investment required. | Higher risk due to the upfront investment in technology and training. |

| Long-term Strategy | May lead to dependency on external providers. | Builds internal capabilities and assets, beneficial for long-term growth. |