Resin vs FDM 3D Printing: Making Your Decision for Miniatures

3D printing has revolutionized the world of miniatures, offering enthusiasts and professionals the ability to create highly detailed, customizable figures right from their homes or workshops. Two of the most popular 3D printing technologies for creating miniatures are resin and FDM (Fused Deposition Modeling) printing. While both methods have their strengths, they differ significantly in terms of print quality, materials, cost, and ease of use. In this article, we’ll compare resin and FDM 3D printing to help you determine which technology is best suited for your miniature-making needs.

Resin 3D Printing

Resin 3D printing, also known as SLA (Stereolithography) or DLP (Digital Light Processing), uses a liquid photopolymer resin that is cured by UV light. The printer builds the model layer by layer, with each layer being selectively exposed to UV light to harden the resin. This process allows for incredibly high detail and smooth surfaces, making it ideal for printing miniatures.To better understand how this method compares to other 3D printing techniques, such as using filament, consider exploring the article, Resin 3D Printing vs. Filament 3D Printing—Essentials You Should Know.

FDM 3D Printing

FDM 3D printing, also known as FFF (Fused Filament Fabrication), works by extruding melted plastic filament through a heated nozzle, building the model layer by layer. FDM is the most common and accessible type of 3D printing, with a wide range of printer options and materials available.For a deeper understanding of this prevalent technology, delve into our comprehensive guide titled, What Is FDM 3D Printing?

Resin VS FDM 3D Printing for Miniatures: Advantages and Disadvantages

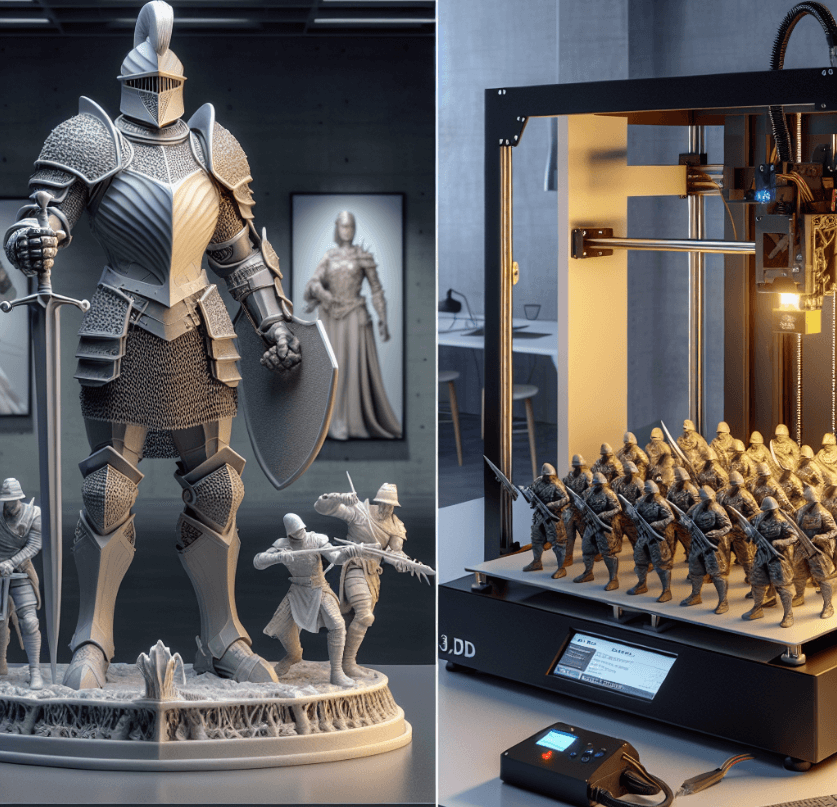

Print Quality and Detail

When it comes to print quality and detail, resin 3D printing has a clear advantage over FDM. Resin printers can achieve much higher resolutions, with layer heights as low as 10 microns, resulting in prints with exceptional detail and smooth surface finishes. This makes resin printing ideal for creating miniatures with intricate features and fine details, such as facial expressions and clothing textures. In contrast, FDM prints typically have lower resolution and visible layer lines, making it challenging to achieve the same level of detail as resin prints.

Material Properties and Durability

FDM printing offers a wider range of materials, including PLA, ABS, PETG, and exotic filaments like wood or metal composites. These materials generally result in stronger and more durable prints compared to resin. Resin prints, on the other hand, can be brittle and may be prone to breakage if not handled carefully. However, the liquid resin used in resin printing can be messy and potentially toxic, requiring careful handling and post-processing.Considering these unique characteristics and requirements, finding a reliable service provider is crucial for achieving the best results. Explore our curated list of the Best Online 3D Printing Services to discover providers who excel in handling these diverse materials and can guide you towards achieving your desired outcome.

Build Volume and Print Speed

FDM printers typically have larger build volumes compared to resin printers, allowing for the creation of bigger miniatures or multiple smaller ones in a single print. This can be advantageous when working on larger projects or producing many miniatures at once. However, achieving high-quality prints with FDM technology often requires longer print times. Resin printing, while limited in build volume, can produce highly detailed miniatures relatively quickly.

Cost and Accessibility

FDM printers and their materials are generally more affordable and accessible compared to resin printers. This makes FDM a more budget-friendly option for those starting out with 3D printing or working on a tight budget. Resin printing, while offering superior print quality, comes with higher material costs and may require a more significant initial investment in the printer itself.Understanding the overall costs associated with 3D printing can help prospective users make a more informed choice. For a comprehensive look at these costs, check our post on How Much Does It Cost to 3D Print Things?

Post-Processing

Both resin and FDM prints require post-processing, but the methods differ. Resin prints need to be washed in isopropyl alcohol to remove excess resin and then cured under UV light to achieve their final strength and durability. FDM prints, on the other hand, require support removal and sanding to improve the surface finish. While support removal and sanding may be easier and less messy compared to washing and curing resin prints, achieving a smooth surface on an FDM print can be time-consuming.

Resin VS FDM 3D Printing for Miniatures: Which Is Better?

If your priority is creating highly detailed miniatures with intricate features and smooth surfaces, resin 3D printing is the way to go. The exceptional print quality and resolution offered by resin printers make them ideal for crafting figurines that showcase fine details like facial expressions, clothing textures, and delicate accessories. However, be prepared to invest more time and effort into post-processing and handle the potentially messy and toxic liquid resin with care.

On the other hand, if you’re looking for a more budget-friendly option or plan to create larger miniatures or multiple prints simultaneously, FDM 3D printing may be the better choice. While FDM prints may not match the detail and surface quality of resin prints, they offer greater flexibility in terms of materials, build volume, and ease of post-processing. With proper techniques and patience, it’s still possible to create impressive miniatures using FDM technology.Whichever technology you choose, our factory QSY offers unmatched 3D printing customization, enabling you to imagine, design, and produce unique objects tailored specifically to you.