How to Bend Sheet Metal for 3D Printing: A Guide to Sheet Metal Fabrication – QSYrapid

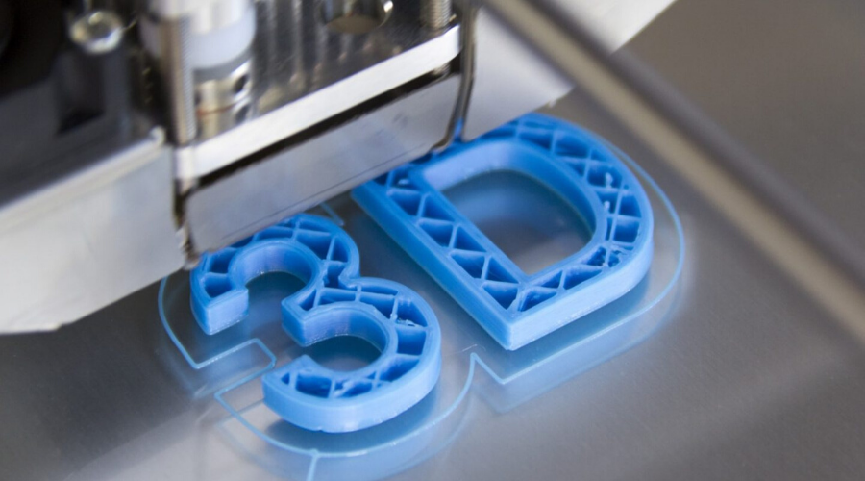

Sheet metal is a popular material used in various industries, from aerospace and automotive to consumer products and electronics. With the rise of 3D printing and rapid prototyping, sheet metal fabrication has become an important process in creating functional and high-quality products. But do you know how to bend sheet metal in the 3D printing process? In this article, we will explore how to bend sheet metal for 3D printing, and introduce the sheet metal fabrication services of QSYrapid.

Understanding Sheet Metal Bending

Sheet metal bending is the process of forming a piece of sheet metal into a desired shape by applying force. The bending process can be done manually or by using a machine, such as a press brake. In order to achieve the desired shape, the sheet metal needs to be bent at a specific angle and radius.

Sheet Metal Fabrication Services by QSYrapid

QSYrapid offers sheet metal fabrication services for a wide range of industries and applications. With years of experience and a team of skilled professionals, QSYrapid can provide custom sheet metal parts and prototypes with high accuracy and quality. The sheet metal fabrication services offered by QSYrapid include:

Bending: With advanced bending machines and skilled operators, QSYrapid can bend sheet metal with high precision and repeatability. The company can bend a variety of metals, such as steel, aluminum, and copper, into different shapes and angles.

Welding: QSYrapid also provides welding services for sheet metal parts, including spot welding, TIG welding, and MIG welding. The welding process is done by experienced professionals and is inspected for quality and strength.

Cutting: QSYrapid offers cutting services for sheet metal, including laser cutting and waterjet cutting. These cutting methods provide high accuracy and clean edges for the sheet metal parts.

Tips for how to Bend Sheet Metal in 3D Printing

When designing sheet metal parts for 3D printing, there are a few tips to keep in mind for how to bend sheet metal:

Use appropriate bend radius: The bend radius determines the minimum radius that the sheet metal can be bent without cracking. The bend radius should be at least equal to the thickness of the sheet metal for successful bending.

Design for symmetry: Symmetrical designs can help to ensure consistent and accurate bending results. It’s important to consider the position of the bend lines and the placement of the part on the bending machine.

Avoid sharp angles: Sharp angles can cause the sheet metal to buckle or crack during bending. It’s recommended to use rounded corners and angles for successful bending.

Conclusion

In conclusion, sheet metal fabrication is an important process in 3D printing and rapid prototyping. With the sheet metal fabrication services offered by QSYrapid, you can get high-quality and custom sheet metal parts and prototypes for your next project. By following these tips for successful sheet metal bending, you can ensure accurate and consistent results.