Quality 3D Prints: Unveiling the Turnaround Time for Your Project!

Typically, for a straightforward, small to medium-sized print with standard materials and shipping within the same country, you can expect the whole process from ordering to delivery to take anywhere from a few days to 2 weeks. For complex, large, or custom materials projects, or if international shipping is involved, it might take 3-4 weeks or more. This timeline can be influenced by several key factors, which we will explore in this article:

Design Complexity

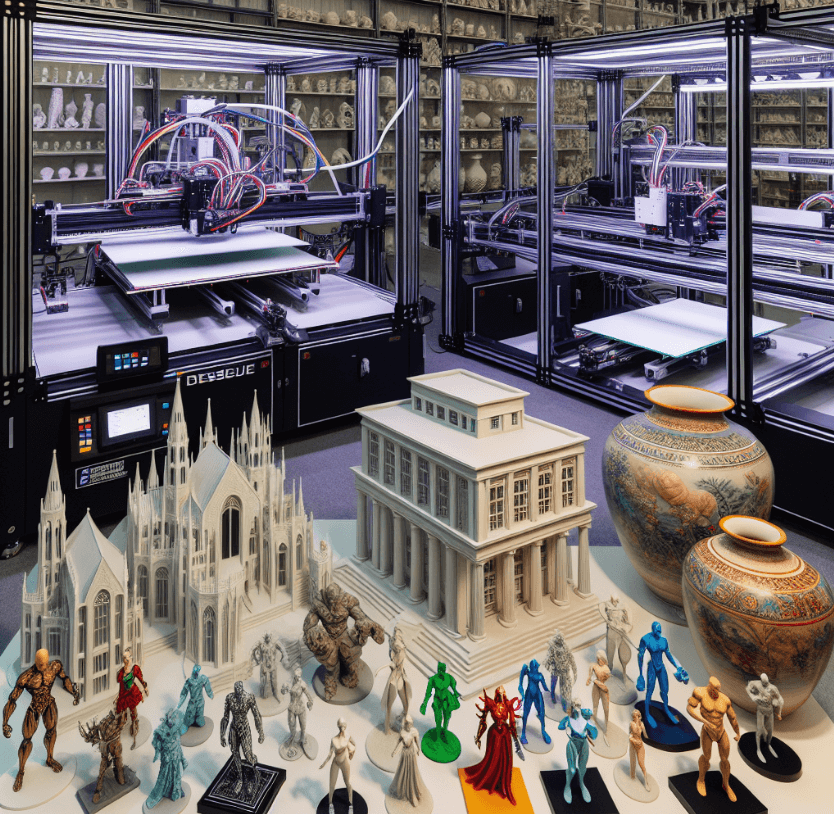

The complexity of your desired 3D print significantly dictates how long you’ll wait before it’s in your hands. Think of it this way: a simple, straightforward design—a basic cube, for example—can be swiftly moved through the printing process, often in just a few short hours. However, a design teeming with intricacies, such as a detailed architectural model or an action figure with multiple moving parts, demands a meticulous printing approach. Each tiny detail needs to be reproduced faithfully, which means the printer works slower, ensuring precision. This careful attention to detail can push the printing time out to several days. It’s a matter of precision versus speed; the more complex your design, the longer you’ll need to wait, but for a result that’s truly worth it. And when time is of the essence, knowing that QSY can help your ideas come true, with a team that’s available 24/7, can be the reassurance you need that your parts will be manufactured with both speed and quality in mind.

Print Size

The scale of your print plays a straightforward yet crucial role in determining how long before it’s ready. Small items, such as jewelry pieces or miniature figurines, can usually be printed within a day because they require less material and the printer can complete them in fewer passes. Larger objects, think of a full-size helmet or a large decorative vase, require a much larger amount of material and significantly more time for the printer to layer this material into the final shape. As the printer methodically adds each layer, the time ticks upward, making larger prints a longer commitment. The key takeaway here is simple: the bigger the object, the longer the print time, as the printer has to cover more ground, quite literally, layer by layer.

Print Material

The choice of material for your 3D print not only influences the look and feel of the final product but also affects how long you’ll be waiting for it. Common materials like Polypropylene(PP) and ABS (Acrylonitrile Butadiene Styrene) are popular for a reason: they’re versatile and print relatively quickly, making them a go-to for both beginners and seasoned printers alike. These materials melt and cool at rates ideal for a swift printing process. However, when you venture into the realm of specialty materials like TPU (Thermoplastic Polyurethane), known for its flexibility, or nylon, prized for its strength and durability, patience becomes a virtue. These materials often require a slower print speed to achieve the high-quality finish they’re known for. This is due to their unique properties, such as flexibility or the need for a more controlled cooling process to prevent warping. The upshot is that while these materials can give your print the exact characteristics you need, they do demand a bit more time on the printer’s part to get everything just right.

Post Processing

Once the printing process concludes, a model isn’t always ready to head straight out the door. Depending on what you’ve created, there may be a few more steps to take. Cleaning is a common necessity; this might mean removing support structures or smoothing out surfaces to achieve the desired finish. For prints made from resin, curing under UV light is a crucial step to harden the material properly. And then there’s painting or applying any other finishes, which can transform a simple print into a vibrant, lifelike model. Each of these post-processing activities requires time and care, adding a bit more wait before you can hold the finished product. It’s not just about the printing; it’s about refining the print into the final vision you had in mind, which naturally extends the timeline.

Lead Time

Imagine you’ve placed your order. Now, the countdown begins, but not necessarily the printing. The gap between your order being placed and the moment the printing starts is what we call lead time. This waiting period can be as varied as the prints themselves, influenced by the print service’s current workload, how readily available the needed materials are, and the specifics of your order. Some print services can fast-track your order for an added fee, pushing you up the queue, while others might be swamped, extending this preliminary wait. It’s an important factor to consider, especially if you’re working against a deadline. Lead time is the silent span that needs to be factored into your planning, as it can stretch the process even before the actual printing begins.

Shipping

The final leg of your 3D print’s journey to you is, of course, shipping. The distance it needs to travel and how it gets to you play pivotal roles in how long you’ll be waiting. If you’re ordering from within your own country, you’re likely looking at a pretty swift transit, possibly even overnight delivery for those especially eager. However, if your order is crossing borders, there’s more than just distance at play. International shipping means dealing with customs, which can introduce delays, and depending on the shipping method, the journey might take considerably longer. It’s the last variable in the equation of how long from click to delivery, and it’s influenced by geography, shipping options, and sometimes, a bit of luck with how smoothly everything runs through customs and delivery networks.

Final Words

Ordering a high-quality 3D print online involves multiple steps, influenced heavily by the design’s complexity and your shipping choices. Working with experienced 3D printing manufacturers is key. They not only turn your ideas into reality but also help you navigate through decisions affecting the timeline, from selecting materials to understanding post-processing needs. By knowing these factors, you can better plan and set realistic timelines for your projects. Remember, patience pays off when it comes to 3D printing. The expertise of 3D printing manufacturers ensures that the final product is worth the wait, reflecting both your vision and exceptional quality.