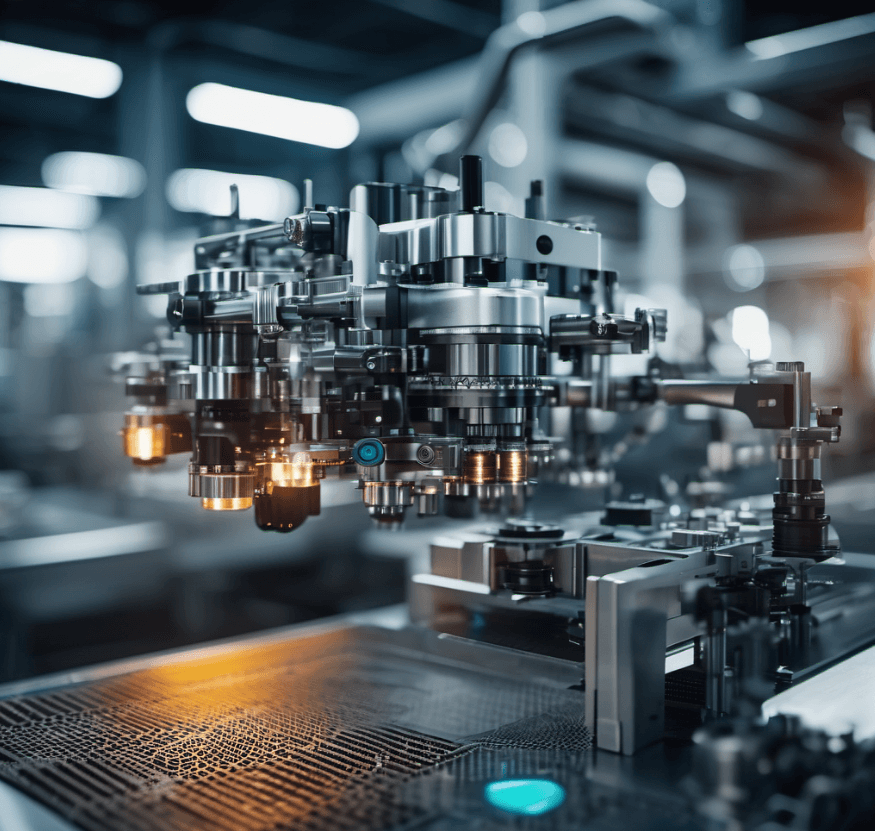

MJF 3D Printing: Precision Meets Speed in Manufacturing

Multi Jet Fusion (MJF) is known for its precision, efficiency, and versatility, especially when it comes to polyamide (PA) materials. Unlike traditional manufacturing methods, MJF offers unparalleled design freedom and the ability to produce parts with complex geometries in a fraction of the time. This article aims to throw light on MJF technology, exploring how it works, its materials, design considerations, applications, and the advantages and challenges it presents. Furthermore, we look towards its future in the manufacturing sector.

Working Principle of MJF

MJF starts with laying a thin layer of polyamide powder on the build platform. Polyamide, known for its durability and flexibility, serves as the primary material in this sophisticated printing process. Following the preparation of this powder bed, MJF employs an innovative approach using thermal inkjet arrays. These arrays precisely deposit fusing and detailing agents across the powder surface according to the design’s requirements. The fusing agent promotes melting, while the detailing agent ensures fine edges and surface finish.

Upon the application of these agents, infrared lamps pass over the bed, providing the necessary energy to activate the fusing agent. This activation leads to the targeted areas of the polyamide powder melting and fusing together to form a solid layer. The areas without the fusing agent remain powder, supporting the structure as it builds up. This selective fusing is crucial, allowing MJF to fabricate parts with complex internal structures and detailed features that would be challenging or impossible to achieve through traditional subtractive manufacturing methods.

After the completion of one layer, the build platform lowers, and a new layer of powder is spread on top. The process of depositing agents and fusing repeats, with each layer bonding to the one below it, gradually constructing the object in a precise upward fashion. This iterative process continues until the entire object is completed, embodying the envisioned design with remarkable accuracy and mechanical strength.

The layer-by-layer approach, combined with the precision of thermal inkjet arrays and the consistent energy provided by infrared lamps, ensures that each section of the object is created with exact detail and uniformity. This meticulous process results in final products that boast fine detail, excellent surface finish, and superior mechanical properties, setting a new standard in the realm of additive manufacturing.

Materials

Polyamide, particularly PA12, stands at the forefront of materials selected for MJF technology due to its exceptional balance between strength and flexibility. This equilibrium allows PA12 to be incredibly durable, capable of withstanding physical stresses without yielding or breaking. This durability is further complemented by PA12’s remarkable chemical resistance, making it resilient against various chemicals, including oils and alcohols, thereby ensuring the longevity of the manufactured parts in diverse environments.

The inherent stability of PA12 over time is another key attribute. Unlike materials that might degrade or weaken, PA12 retains its mechanical properties and resistance, ensuring that parts manufactured today will continue to perform in the future without significant degradation.

However, MJF doesn’t limit itself to the use of PA12 alone. The technology’s versatility is showcased through its capacity to integrate additional materials into the printing process. For instance, the incorporation of glass beads within the polyamide matrix serves to enhance the rigidity of the final product. This is particularly beneficial in applications where structural stability under physical loads is paramount.

Similarly, the inclusion of aluminum powder into the mix aims at boosting the thermal conductivity of the parts, which is a consideration crucial for anyone making material choices, such as between titanium or aluminum, in processes like CNC and 3D printing. Such an enhancement is essential for components operating in environments where efficient heat dissipation is required, like heat sinks in electronic devices.

This strategic integration of supplementary materials with PA12 not only amplifies the specific properties required for certain applications but also broadens the scope of MJF technology. By fine-tuning the material composition, MJF can produce parts that are not just mechanically robust and durable but also customized to meet specific performance criteria, such as improved thermal management or increased structural integrity.

Design Considerations

Optimizing Wall Thickness

In the context of MJF, the thickness of the walls in your design is more than just a matter of dimensions; it’s a balancing act. The goal is to maintain the part’s structural integrity, ensuring it can withstand the intended use without failure. At the same time, it’s important to avoid unnecessarily thick walls that could lead to material wastage and increased production costs. The optimal wall thickness varies by application but generally should be designed to support the part’s functionality, which is a critical aspect of the broader design rules for 3D printing.

Strategic Placement of Escape Holes

Escape holes play a pivotal role in the MJF process, serving as conduits for removing unused powder trapped inside hollow or enclosed sections of the printed part. These holes must be strategically placed to ensure complete powder removal, which is crucial for the part’s weight and material efficiency. Additionally, the size and number of escape holes should be carefully considered to balance powder removal with the structural aesthetics of the final product.

Careful Orientation of the Part

The orientation of a part during the printing process significantly impacts its support requirements, surface finish, and even mechanical properties. Designing with orientation in mind can reduce the need for support structures, which, in turn, minimizes post-processing work and potential surface blemishes. Proper orientation can also influence the part’s strength, with certain alignments offering greater resistance to stresses based on the layer-by-layer construction.

Managing Shrinkage and Warping

Polyamide materials, commonly used in MJF, exhibit certain behaviors during the cooling phase, such as shrinkage and warping. These factors can affect the dimensional accuracy of the final part, deviating from the intended design specifications. To mitigate these effects, designers must account for potential dimensional changes that can occur with polyamide materials, which is a crucial step in avoiding common issues when creating 3D printed prototypes. This may involve adjusting dimensions or incorporating design features that counteract the material’s tendencies to warp or shrink, ensuring the finished part aligns closely with the original design intent.

Applications

MJF’s widespread applicability showcases its transformative impact across various sectors

- Medical Field: Custom-fitted prosthetics, patient-specific surgical guides, and implants designed for biocompatibility and precision.

- Automotive Sector: Lightweight, durable components for vehicles, including parts that withstand extreme temperatures and mechanical stress.

- Consumer Products: Personalized goods like wearables and phone cases, featuring intricate designs and custom finishes.

- Aerospace Industry: High-strength, lightweight parts for aircraft and spacecraft, where durability and weight reduction are critical.

- Manufacturing Tools: Creation of custom jigs, fixtures, and tooling for manufacturing lines, improving efficiency and reducing lead times.

- Architecture and Construction: Detailed architectural models and custom components for construction, enhancing design visualization and project planning.

- Fashion and Jewelry: Customized accessories and intricate jewelry designs that allow for high levels of personalization and complex geometries.

- Education and Research: Prototypes for academic research and educational models, facilitating hands-on learning and experimentation.

This broad utilization paves the way for a discussion on who can really benefit from a 3D printing online service, looking into the specific needs and advantages for each sector.

Advantages of MJF Technology

- Complex Geometries: MJF excels at producing parts with intricate designs and complex internal structures in a single print run, eliminating the need for assembly.

- Streamlined Manufacturing: The process simplifies the manufacturing workflow, reducing steps and potential points of failure, leading to a more efficient production line.

- High Quality and Consistency: MJF is known for its ability to produce parts with high precision and uniformity, ensuring consistent quality across batches.

- Speed of Production: Compared to traditional manufacturing and some additive manufacturing methods, MJF offers faster turnaround times from design to final product.

- Cost and Time Savings: The efficiency of MJF, combined with its speed and ability to reduce assembly requirements, can lead to significant reductions in both production costs and time to market.

Challenges of MJF Technology

- Initial Investment: The upfront cost of acquiring MJF equipment is significant, posing a barrier to entry for small to medium-sized enterprises.

- Material Selection: While the range of materials suitable for MJF is growing, it remains narrower than that available for traditional manufacturing processes, limiting some applications.

- Post-Processing Requirements: Despite the streamlined printing process, MJF parts often require post-processing, such as powder removal and surface finishing, which can extend the total production time and add to costs.

Future Outlook

The future of Multi Jet Fusion (MJF) technology is poised for exciting advancements that promise to significantly impact 3D printing manufacturers and transform operations within 3D printing factories:

- Expanding Material Options: Emerging materials, including advanced polyamides and composite substances, will allow manufacturers to explore new applications and functionalities, pushing the boundaries of what can be created with MJF technology.

- Increasing Printing Speed: Technological enhancements are expected to drastically accelerate the printing process. This will enable factories to fulfill orders faster, increasing productivity and meeting the market’s growing demand for rapid manufacturing.

- Reducing Costs: Innovations aimed at making MJF equipment more affordable and reducing operational expenses will make this technology accessible to a broader range of businesses, from startups to established enterprises, democratizing high-quality 3D printing.

- Improving Accessibility for 3D Printing Manufacturers: Advances in software tools and user interfaces will simplify the transition from design to printed object, enabling companies to leverage MJF technology with minimal learning curves and significantly streamline their production workflows.

- Focusing on Sustainability: Efforts to minimize material waste and optimize energy use are set to make MJF one of the most eco-friendly options in the 3D printing landscape. The development of recyclable materials and more efficient machines will help manufacturers reduce their environmental footprint.

- Enabling Customization at Scale: MJF technology will further facilitate the production of customized items in small batches or even single units, meeting the consumer demand for personalized products without sacrificing speed or cost-effectiveness.

- Advancements in 3D Printing Factories: With the integration of automated post-processing and quality control systems, factories will see improvements in the consistency and reliability of printed parts, enhancing the overall quality of products available in the market.

It is apparent that the evolution of Multi Jet Fusion (MJF) technology is set to revolutionize 3D printing by expanding material options and increasing production speeds, making it more accessible and sustainable. These advancements will enable 3D printing manufacturers to create more complex and customized products efficiently. As MJF becomes more integrated into manufacturing processes, we’ll see a significant shift towards quicker, more cost-effective, and eco-friendly production methods. This progress promises to enhance the capabilities of 3D printing factories, marking a significant leap forward in additive manufacturing’s precision, flexibility, and environmetal responsibility.